Okay, here's a pic of my problem, hope this will help all who are willing..

| LOST JEEPS http://www.lostjeeps.com/forum/phpBB3/ |

|

| Diff again... http://www.lostjeeps.com/forum/phpBB3/viewtopic.php?f=5&t=44304 |

Page 1 of 2 |

| Author: | mackruss [ Thu Jun 18, 2009 1:07 pm ] |

| Post subject: | Diff again... |

Hi Folks I noticed some fresh oil on the driveway tonight and had a look underneath. There is diff oil seeping out the front of the diff where it connects to the driveshaft, sorry to the purists for my lack of the correct terminology. When driving i can hear a whine especially evident when i tap of the gas. Can anyone help from my explanation or if not I'll post some pics over the weekend. Thanks in advance. |

|

| Author: | gmctd [ Thu Jun 18, 2009 2:24 pm ] |

| Post subject: | |

From your description, the pinion seal may be leaking - replacement requires removing the pinion yoke |

|

| Author: | mackruss [ Thu Jun 18, 2009 3:02 pm ] |

| Post subject: | |

Probably is, easy job or one of those PIZA jobs ? |

|

| Author: | gmctd [ Thu Jun 18, 2009 3:15 pm ] |

| Post subject: | |

Not especially easy, but not 2 difficult................. |

|

| Author: | warp2diesel [ Thu Jun 18, 2009 5:43 pm ] |

| Post subject: | Always check the vent |

When I was in the repair business, I replaced a lot of differential housing seals and transmission seals that were blow out due to stuck vents. You may unclog the vent and have the leak stop with out replacing the seal, but check it anyway, good SOP! |

|

| Author: | mackruss [ Fri Jun 19, 2009 2:05 am ] |

| Post subject: | Re: Always check the vent |

warp2diesel wrote: When I was in the repair business, I replaced a lot of differential housing seals and transmission seals that were blow out due to stuck vents. You may unclog the vent and have the leak stop with out replacing the seal, but check it anyway, good SOP!

I'll do that if i know what i'm looking for, is the vent on top of the diff as i located a black connector with nothing plugged into it? Once again thanks for the help. |

|

| Author: | warp2diesel [ Fri Jun 19, 2009 9:43 am ] |

| Post subject: | Re: Always check the vent |

mackruss wrote: warp2diesel wrote: When I was in the repair business, I replaced a lot of differential housing seals and transmission seals that were blow out due to stuck vents. You may unclog the vent and have the leak stop with out replacing the seal, but check it anyway, good SOP! I'll do that if i know what i'm looking for, is the vent on top of the diff as i located a black connector with nothing plugged into it? Once again thanks for the help. Vent is either on top or there is a hose connection going to the vent in a remote location to keep it out of the water. I suspect our CRDs have a hose going to the vent. |

|

| Author: | mackruss [ Fri Jun 19, 2009 11:22 am ] |

| Post subject: | |

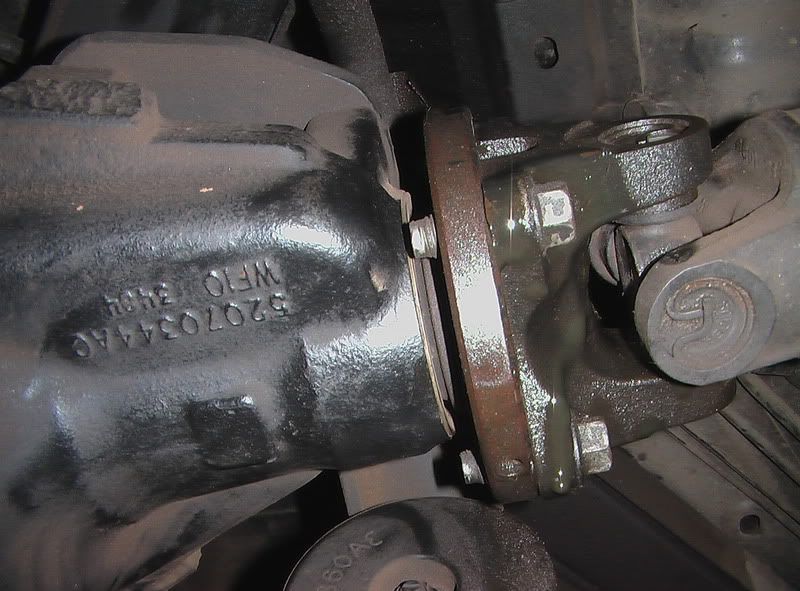

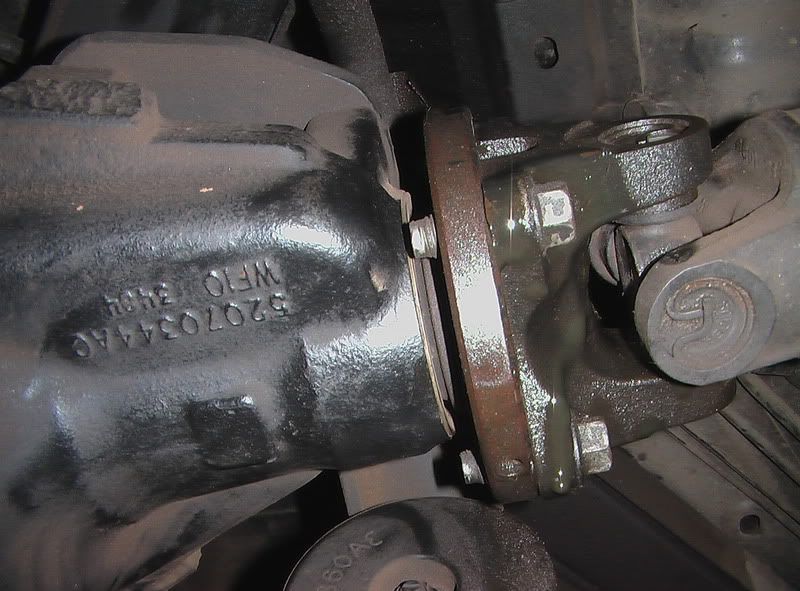

Okay, here's a pic of my problem, hope this will help all who are willing..

|

|

| Author: | Turbo Tim [ Fri Jun 19, 2009 7:52 pm ] |

| Post subject: | |

Pinion seal looks dry. (Pinion seal is closest to housing, behind the U-Joint mounting plate. I think the seal that seals the pinion shaft splines to the yoke housing is leaking. This would be just under the nut, or the nut could be loose. |

|

| Author: | mackruss [ Sat Jun 20, 2009 2:20 am ] |

| Post subject: | |

Turbo Tim wrote: Pinion seal looks dry. (Pinion seal is closest to housing, behind the U-Joint mounting plate. I think the seal that seals the pinion shaft splines to the yoke housing is leaking. This would be just under the nut, or the nut could be loose.

I'm still a bit hesitant to tackle this one. Can i loosen the 4 nuts by applying pressure on the diff? Once i've removed the yoke, is it possible to tighten the nut then and do i need a special tool. I can feel play in the flange so i do suspect a loose nut. |

|

| Author: | Joe Romas [ Sat Jun 20, 2009 7:59 am ] |

| Post subject: | |

mackruss wrote: I'm still a bit hesitant to tackle this one.

Can i loosen the 4 nuts by applying pressure on the diff? Once i've removed the yoke, is it possible to tighten the nut then and do i need a special tool. I can feel play in the flange so i do suspect a loose nut. Since you've gotten no replies yet I'll tell you what little I know about that area. There is a special "crush washer" in that area and it yeilds a certain amount when it's properly torqued. this all is necessary to maintain proper alignment between the pinion gear that is on that shaft to the big ring gear. The fact you have a whine indicates this alignment is not correct. |

|

| Author: | bugnout [ Sat Jun 20, 2009 9:19 am ] |

| Post subject: | |

Check the u-joints. I had one freeze up which caused the drive shaft to spin off center. gave a vibration and caused that seal to leak. |

|

| Author: | gmctd [ Sat Jun 20, 2009 1:35 pm ] |

| Post subject: | |

Normally the pinion shaft splined area is cleaned and RTV'ed just prior to installing clean pinion yoke, washer and nut - cured RTV is the shaft\yoke seal - could be as simple as removing the nut\washer, clean yoke\shaft\washer\nut with lacquer thinner, quickly apply fresh bead of RTV around shaft\yoke interface, do the ewasher\nut, and may seal - could be whining due to low lube level, or due to out-of-spec torque make-up on the crush washer, as noted |

|

| Author: | mackruss [ Sat Jun 20, 2009 3:06 pm ] |

| Post subject: | |

gmctd wrote: Normally the pinion shaft splined area is cleaned and RTV'ed just prior to installing clean pinion yoke, washer and nut - cured RTV is the shaft\yoke seal - could be as simple as removing the nut\washer, clean yoke\shaft\washer\nut with lacquer thinner, quickly apply fresh bead of RTV around shaft\yoke interface, do the ewasher\nut, and may seal - could be whining due to low lube level, or due to out-of-spec torque make-up on the crush washer, as noted

So i need to loosen the 4 bolts and slide the yoke off the flange this will allow me access to the nut. Loosen the nut and remove the washer and reseal with RTV and then replace washer and nut and remount. |

|

| Author: | warp2diesel [ Sat Jun 20, 2009 3:44 pm ] |

| Post subject: | Clean it off with Break Cleaner before.... |

mackruss wrote: gmctd wrote: Normally the pinion shaft splined area is cleaned and RTV'ed just prior to installing clean pinion yoke, washer and nut - cured RTV is the shaft\yoke seal - could be as simple as removing the nut\washer, clean yoke\shaft\washer\nut with lacquer thinner, quickly apply fresh bead of RTV around shaft\yoke interface, do the ewasher\nut, and may seal - could be whining due to low lube level, or due to out-of-spec torque make-up on the crush washer, as noted So i need to loosen the 4 bolts and slide the yoke off the flange this will allow me access to the nut. Loosen the nut and remove the washer and reseal with RTV and then replace washer and nut and remount. ... you apply the RTV. You want the surfaces to be chemically clean before you put on the RTV, that way it will bond and seal. I had a field fix on a piece of waste water equipment that used silicone sealant (RTV) to keep a gutter tray from leaking poop sludge all over the floor. Out of all the ones I did they held and did not leak. If you slop the RTV on with oil or grease on the surface and you stand a good chance of a leak. |

|

| Author: | scrambledKJ [ Sat Jun 20, 2009 8:40 pm ] |

| Post subject: | leak |

Your leak seems to be pretty big. I would remove the 4 bolts and slide the drivesgaft out of the way. The round pinion yoke should have no play "up and down" or "in and out". If there is, I would assume a bad pinion bearing. This would also account for the noise. Growling on acceleration is the drive side of the gears contacting improperly. This is usually from a bad bearing allowing the pinion to walk further into the housing. If the bearing have gone bad, I would recommend a complete rebuild with new bearings, seals and gears. I have built many rear ends and they never work as nicely when patched back together with pinion bearings. Travis |

|

| Author: | Xterra2KJ [ Mon Jul 27, 2009 3:49 pm ] |

| Post subject: | |

I had the same problem, after I changed the U-joints it cleared up. I keep a spare with me now just in case. lol |

|

| Author: | kdlewis1975 [ Mon Jul 27, 2009 9:48 pm ] |

| Post subject: | |

Mine has a leak too. It isn't nearly as bad as Mackruss's. Mine does appear to be from the area of the seal. It's mild. I don't have dripping, but there's an even coating everywhere. Having a bad u-joint was suggested. Because I get a mild thunk from time to time on take-off, I'm wondering if the ball joint in the tri-link is bad. Could this potentially lead to the leak? |

|

| Author: | Xterra2KJ [ Tue Jul 28, 2009 12:47 pm ] |

| Post subject: | |

Funny you said that, my kj is at home on the lift right now. I thought my trans was going when i heard some disturbing noise from underneath... come to find out that the rear upper ball joint and body mount bushings were completely shot which makes a lot of noise...Fixing that first thing after work. |

|

| Author: | mackruss [ Wed Jul 29, 2009 1:36 am ] |

| Post subject: | |

Hi Guys I sent her in yesterday on a flatbed to a repair shop that has rebuilt Dana 44 diffs mant times rather than take a chance. I'll let you know the outcome for those of you who have a similar problem. |

|

| Page 1 of 2 | All times are UTC - 5 hours [ DST ] |

| Powered by phpBB © 2000, 2002, 2005, 2007 phpBB Group http://www.phpbb.com/ |

|