Well, the decision was just made for me:

Time for new calipers.

I did finally get the bleeder valve out by taking the caliper off & putting an extension on my Vice Grips and reefing hard on the sucker.

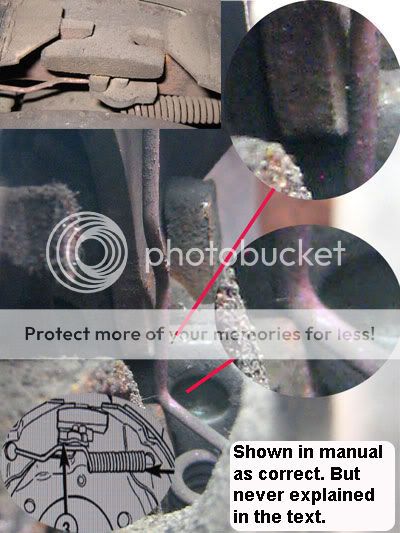

Unfortunately, it was all for not since the caliper won't open - even in a vice. I managed to get the piston to move in only about 1/2". When I pull back the dust boot, yes, there's a bit of rust in there but I don't think I've ever seen any that didn't have at least a bit.

Oh it just needs rear brake pads - $30 & a couple of hours.

No, I guess the rotors are shot too - $75

Of course I'll need brake cleaner - $5

Oh, and I'm out of shop towels - $8

Uh oh, bleeder valves need replacing - $10

Dang nabit, the shoes are bad too - $30

Geez, the calipers won't open? $37 x 2

From $30 ----> $232 . . . and counting.

[/img]

[/img]