tjkj2002 wrote:

Now you just need to convert the torque to a PSI reading,and just because it threaded out with ease does not mean anything.Some bolts are designed to stretch when torqued properly,after a certain amount of stretch they are considered bad.Cummins uses these types of bolts for there cylinder heads and actually have a little tool(ruler type)to measure bolt stretch.

Most modern engines use stretch bolts to prolong the life of the Head Gasket.

Want to know the clamping force for a bolt at a given torque, here you go:

http://www.engineersedge.com/calculator ... e_calc.htmMercedes used to use stretch bolts on their connecting rods where you would measure the waste of the bolt shank to determine if it needed replacement. Others tell you to replace the bolts every time, a good practice.

To put any paranoia to rest, at 270 In-Lbs the tension load on the Torque Converter Bolt is 56,242 PSI.

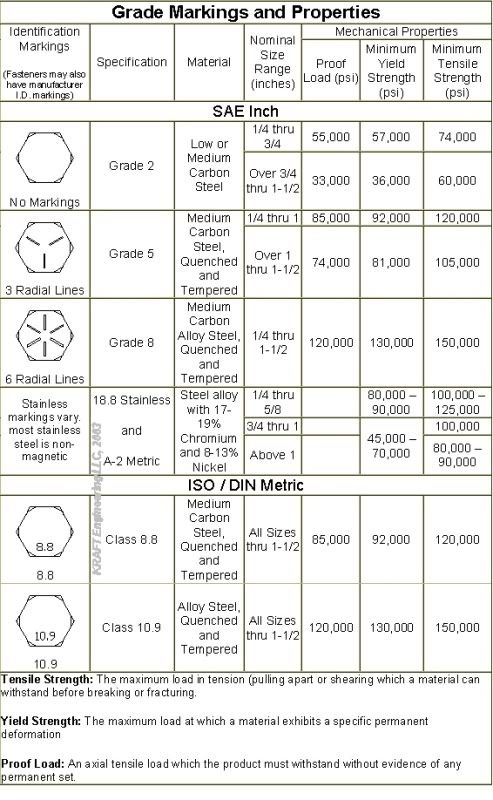

My point is that Chrysler just went to a chart and grabbed a number that is conservative. The torque converter bolts are capable of more and have conservative Safety Factor when torqued dry. Even at 270 In-Lbs torqued with Red Loctite there is still a safety factor, a good safety factor. Lubricating the threads with oil or Loctite does increase the clamping force and the tension on the bolt, but lets face it 56,242 PSI is less than 130,000 PSI. We still have a good safety factor, plus the bolts will not come loose and fail in shear which some members have had experience with.

An Engineer with a Brain would look at the test results, validate them and have no problems recommending Red Loctite instead of going to larger bolts.

Anyone know what size bolts and how many Torque Converter Bolts the Dodge/ Cummins uses with the 68RFE. SunCoast is putting 800 HP through the 68 RFE with a modified input shaft and clutch pack housing. I know they use Red Loctite.