< Given that I've been polluting this forum for months with separate threads pleading for salvation throughout this major surgery, I'm going to condense and consolidate all of that fantastic advice and insight into this thread and credit the advising Supertechs. A dignified and chivalrous platoon of scholars and humanitarians, All.

Many MANY thanks to: BUGNOUT, CEVANS, DENT, DHENDERZ, DREWD, FLASH, FLMAN, GEORDI, GORDNADO, HEXUS, JSAMPS1345, JWS84_02, LACABRERA, LANCER, LOCKED KJ, MASS-HOLE, MOUNTAINMAN, OLYPOPPER, PAPAINDIGO, PETEYZ24, PJIGAR, RANKOM, SIR SAM, THEFUNK, THERMOREX, TJKJ2002, WOODTICK, WWDIESEL, 95Z28A4. Apologies to any others I may have overlooked whom have kindly indulged my newbie threads.

YOU GUYS ARE ALL HEROES !!!

>

HEAD/ARP/TBELT-INSTALL REVIEW (imho)

A1: evaluate what work needs to be done to your cylinder-head.

In my case, this HG job was just preventative; no leaks, warps, dropped-valves, glo-tips or other disasters. Still, I opted to install new exhaust-valves & valve seals (both exh/int). I had a machine-shop:

A. Tank-clean both the head and intake man/cam assembly.

B. Grind the valve seats.

C. Surface the cylinder head.

I also had them install the new exhaust-valves and int/exh stem seals.

Use good judgment; the money you spend addressing head/valve issues while the head is off can repay you 10x against future failure.

While your head is being serviced, use fresh motor oil to slick a coat of protection on the exposed surface of the block and pistons; then cover with lint-free rags until head installation.

Before head installation, use metal-cleaner (brake-cleaner spray adequate) to remove oil residue, and make absolutely certain that the mating surfaces are clean and dry.

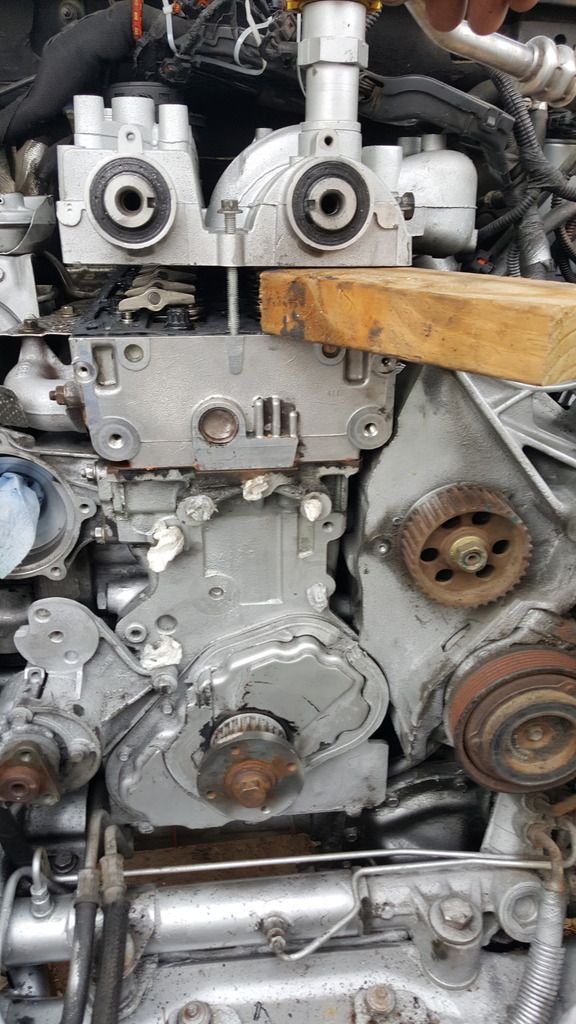

While the HEAD is off it's an excellent time to:

- Replace the motor mounts; tons of access and you're only wrestling the weight of the jacked-up short-block (=300# lighter than complete engine&accessories).

- Replace glo-plugs, sparing some installation grief (post-machining).

While the INTAKE/CAM assembly is off:

- Remove and clean your MAP and CCV using sensor-safe spray cleaner. With all sensors and seals removed, it's also advisable to have a machine-shop tank-clean the entire assembly (or at least DIY spray-clean). The cams/bearings will not be adversely affected by tank-cleaning.

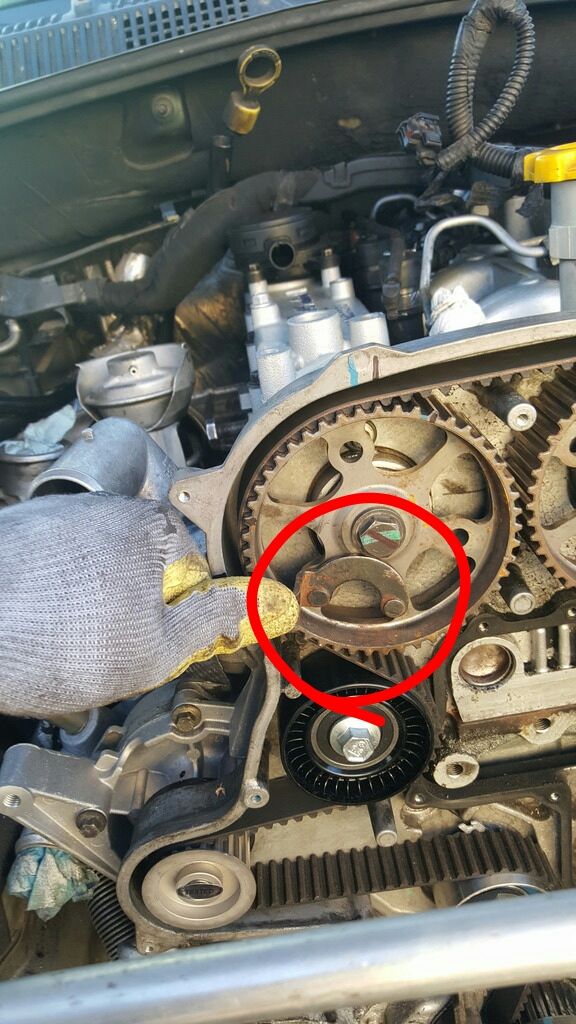

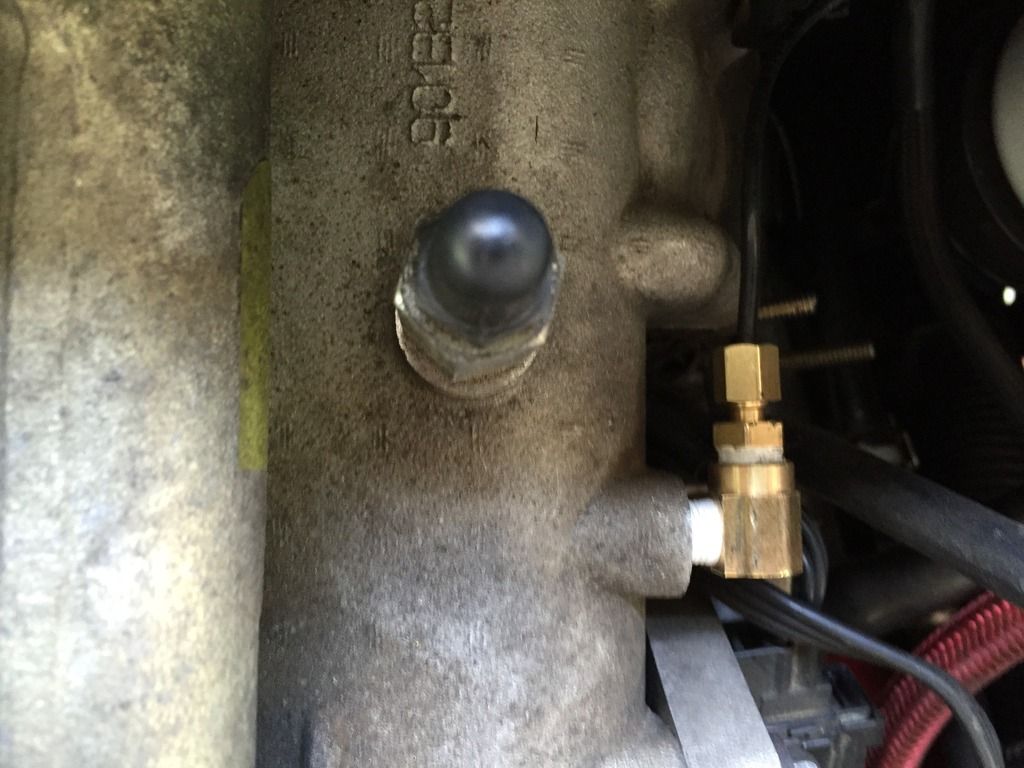

- It's an excellent opportunity to prepare for a future boost-gauge upgrade; drill and tap an eighth-inch (1/8th") NPT (aftermarket standard, correct?) threaded-hole into the intake manifold; excellent existing location to tap pictured, just in front of the main intake port.

LOCATION AND PHOTO COURTESY OF WWDIESEL:

HEAD/ARP INSTALL:

Lightly pre-lube ARPS;

- At nut-end (Un-flared, finer threads);

- At nut threads;

- At both sides of washers.

Do NOT lube ARPs at block threads (flared end of stud, coarser threads).

"Pre-assemble" studs, washers and nut, threading nut until flush with stud-end:

Then install all 18 stud-assemblies until finger-tight.

Proceed to tighten studs in "customary" head-bolt pattern, from center of head to outermost holes in an expanding X pattern.

Commence torque sequence.

A. 40#;

B. 85#;

C. During final tightening sequence, torque the inner 10 studs that border the cylinders to 130#, but the remaining outer 8 studs to 125#.

NO loosening required between B & C.

OPTIONAL:

- Apply a light, even coat of preferred gasket-spray (I used copper) to both sides of head gasket pre-installation (wait 'till tacky).

- Pre-Soak NEW (of course) Rockers in fresh motor oil bath

For a far more secure grip on the ARPs' funky 'star' heads, instead of using a 12-point conventional socket consider obtaining either a set of actual star-sockets or these commonly available "square sine wave" sockets (useful in many situations):

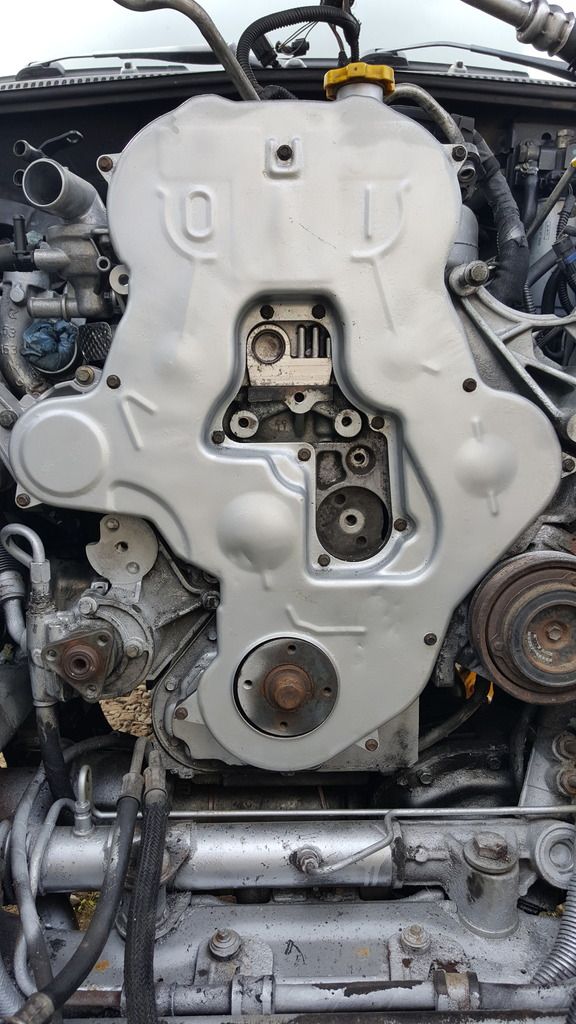

I painted both the valve-cover and tbelt outer cover (don't paint-over your timing marks!!!) with 3 coats of high-temp engine paint and then 3 coats of engine clear-coat (gloss):

Goofy and bored, assuredly, but it does help with locating leaks, cleaning, and contrasting tertiary parts.

Keywords: cylinder-head replacement procedure procedures sequence, timing-belt replacement procedure and special tools (lol), inferior front oil seal alternative alternatives options, 5/8" coolant hose routing layout locations, bored yet super-cool motor-tattooing, historical relationship between calisthenics and engine reassembly.