I clearly don't know what I am talking about, because I assumed the CP3 was mechanically driven and not electrically driven... LOL?

In any case, not having confidence in what I was doing I bailed on the compression test. I like to start with a compression test and then get specific with a leak down test if a cylinder is out of whack as compression tests are easier, but lacking confidence I just dug into the leak down test.

In case anyone doesn't know (I didn't!) the threads on the VM.1072 tool are 1/4" NPT, which shares nothing in common with common spark plug sockets. Both my compression and leak down tester have metric threads for spark plugs, so that was a problem. I ended up buying this:

https://www.lowes.com/pd/Kobalt-Compres ... 1000404921And replacing the valve with a air tool quick disconnect which mated to my leak down tester. It was a pretty convenient solution.

I was able to remove the fan using a cam holding tool:

https://www.amazon.com/OTC-6613-Variabl ... NrPXRydWU=and a very large crescent wrench. Fortunately the nut on the fan was not excessively tight... it came out with only a small fight.

The injectors themselves were also pretty easy to remove - I presoaked them in some Penetro (like Kroil) and was able to wiggle them out. There was a LOT of disgusting sludge around their bodies, probably from years of leaky valve cover or something. Nasty.

I let the engine idle for about 20 minutes prior to starting work. Coolant temp showed 150F (according to OBDII, anyway) which seemed like a good starting place.

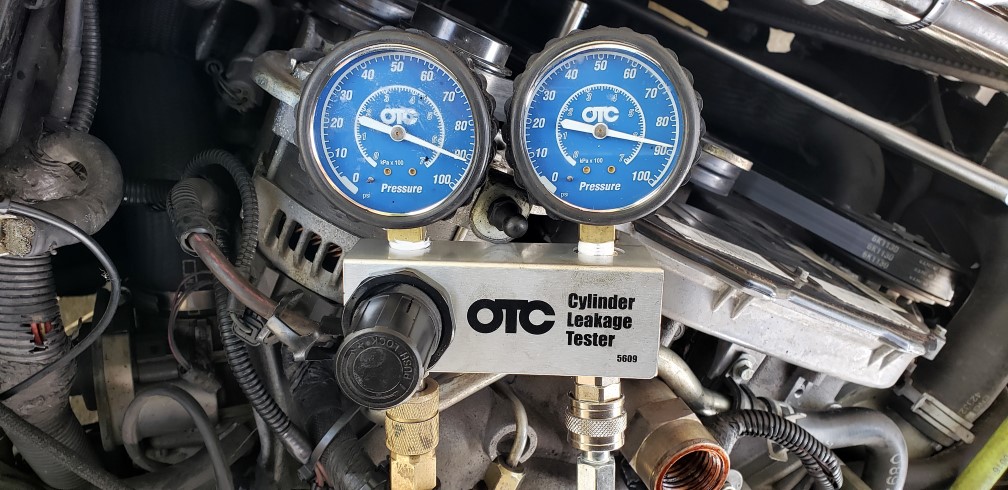

Fan & shroud out, injectors out, VM tool in... leak down test!

Cylinder 1:

Cylinder 2:

Cylinder 3:

Cylinder 4:

Basically 0% leak down, which is (IMHO) VERY impressive. Cylinder #3 shows a tiny amount in the photo, but after taking the picture I adjusted the crank position a couple degrees and got 0%.

This motor has 180k on it and a totally unknown service history.

The thing has basically been sitting for two years. It has a massive oil leak from some invisible place (search LostJeeps for my username.... ugh!), and I'm FINALLY pulling the motor. I am going to do the timing belt and head gasket while it's out, and I wanted to be sure I didn't need anything more invasive. With these great results, I think I can safely say I do not!