Well, I guess we'll never know.

After establishing my crank end play was well within spec, I went about putting the rear bearing carrier back together. It's fidgety assembly for sure - there is an o-ring that goes between the thrust washer and the crank that generally would prefer not to stay put. I used some sticky assembly lube to put it where it should be, and as far as I know, it stayed there.

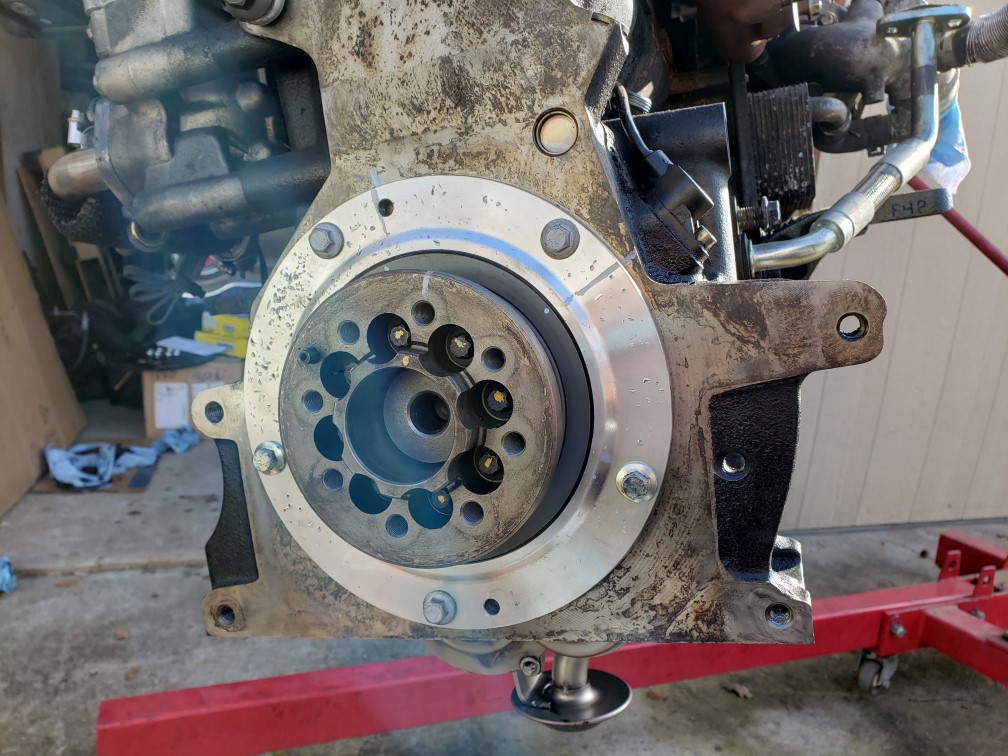

You can see the internal oil slinger on top - I used assembly lube to stick it in place as well.

I used hose assembly lube (which is very slippery) on the o-ring around the circumference of the carrier to prevent the o-ring from binding and getting damaged, and the retaining bolts tightened criss-cross in sequence to gently pull it in. You can see the bearing's oil feed lined up with the oil gallery... this is important if you want your engine to work.

The carrier isn't keyed in any way, so it can be installed incorrectly.

I used blue Loctite on the bolts to ensure they don't go anywhere this time. Spec on those bolts is 33lb ft, and I noticed that three of the bolts would not torque properly... pulling them back out, they were clearly stretched. I replaced them with new, and those torqued up properly. You more or less must install the flex plate adapter to ensure the RMS doesn't go anywhere, so that's on too. (That of course necessitated me buying longer bolts to secure the motor to my engine stand...)

I'm still feeling nervous about carrier bolts, so before putting the motor back in I think I'm going to run over to a local speed shop and pick up ARP 761-1001, which is their stainless M8x20 bolt kit and just know I have nice, new hardware in there. Still turning it over in my head.

I ran out of time, but next weekend I will finally get the oil pan back on. Sometime this week I'll put the order in for the rocker arms and valve cover gasket. I'm ordering this stuff piecemeal in case I run into some major problem and need to abort, but pretty much at this point the sunk investment outweighs the remaining investment... it may be time to just getting all the remaining pieces queued up. IDK.