Shipping costs are out of site so to try a new approach I ended up with a KK roof rack being sent to my place for Ted15

HUGE THANKS to BugginKJ for his experienced welding techniques

Heres how it arrived

Now the fun begins

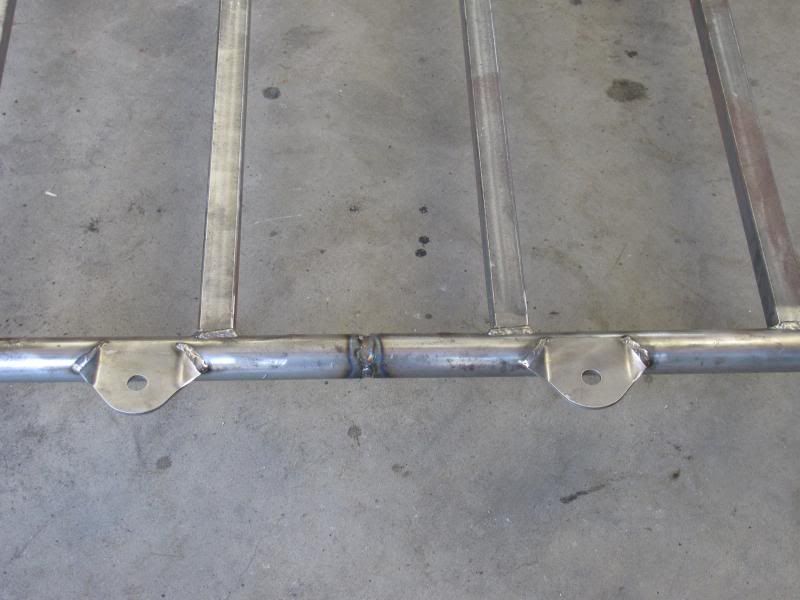

It was cut in the middle, sleeves were provided to slide inside each portion front and rear

these in turn were drilled and plug welded and then fully welded where the cut was.

You can see the sleeve that we inserted laying to the left of the rack

fitment on Teds

after the sleeves were installed, spot welded in and then starting to fully weld them together

due to rain etc did not have time or weather to finish painting

Undoubtedly the strongest rack around or one of