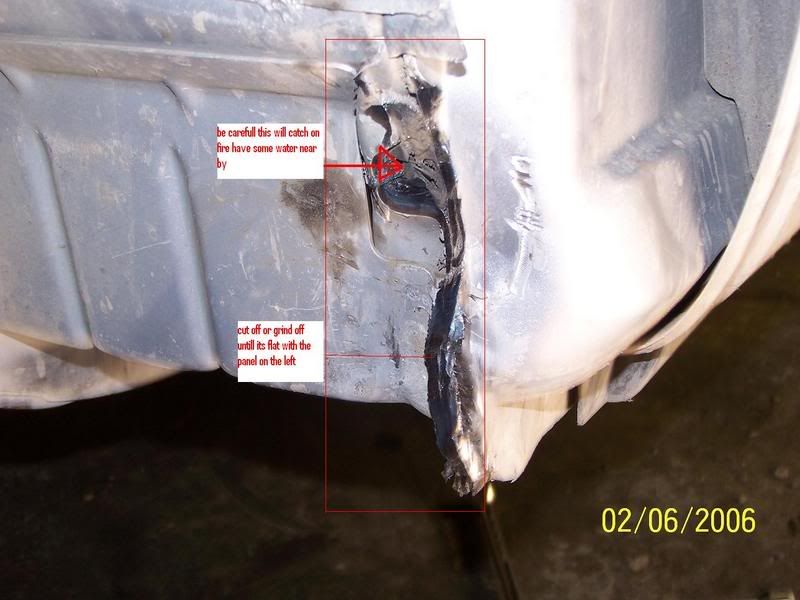

Well I have 31/10.5R15s on my Libby and it was rubbing bad! So I decided to do some cutting and welding on my libby! I ended up cutting the pinch weld

completely off and grinding it down.

If Your weld is folded then un fold it and cut it down till its flat also you will be cutting a bit off the top to left side if weld I cut it off about 4 inches from the bottom.

once that is done it should look something like this

Next I worked on the wall to the left of the pinch weld I used a Air Cutter to do this.

Next Cut the one and right up against the wall to the far left ( Remember this is the driver side of the Jeep) Next your going to do the bottom cuts!^

Once the bottom Cuts are done you will need to do some hammering I used are very large Sludge Hammer and beat the crap out off the pinch weld, the upper wall IN and the bottom wall UP! It look like this after the hammering.

Once all that is done you will need a Migwelder..... Weld all that up and fill in the dents on the pinch weld then grind it so it looks good and fill some more. till its nice and smooth.

once my welds looked good and was smooth I used this Windo-Weld Super Fast Urethane.

I covered all the weld filled all the holes and the whole area where the pinch well was.

Then I did some cutting on the liners that was very easy after I reinstall the liners and flares I used some self tapping screws to push the liner up inside there so the tire will not hit the wall or the liner. Final results looked like this.

this is after 2 weeks of driving and playing in the desert

ALL 3 PICS ARE OF THE PASSENGER SIDE OF JEEP.

I still have some work to do on the Flares. I think over all it was worth it they have not rubbed since the work was done but i have lots of work for the rear to do still.

_________________

2003 KJ Sport

Frankenlift with Spacer in the rear

Jeepin Al's A-Arms

31x10.5R15 Super Swampers TSL Radials

ARB Front Bumper

Warn Winch M8000

Rock Lizard Fab Rear Bumper